In the vast field of aerospace engineering, the margin for error is minuscule, thus amplifying the importance of every component, every process, and every design choice. Among these processes, metal stamping stands as the most crucial cornerstone. However, in the face of the ever-evolving demands of the aerospace industry, how can we determine the best methods for metal stamping of aerospace components?

The Indispensable Role of Metal Stamping in Aerospace

Essentially, metal stamping is the art and science of shaping metal sheets into specific forms using dies. While this process has ancient origins, its modern application, especially in the aerospace sector, is nothing short of revolutionary. The aerospace field requires components that can withstand extreme conditions ranging from temperature fluctuations to high pressure, and metal stamping technology rises to this challenge by providing parts with unparalleled precision and durability.

Precision: The Lifeline of Aerospace Components

Our skies are vast and boundless, and space is infinite. In these expansive realms, the operations of the aerospace industry are of paramount importance. A slight deviation, a minor flaw, or an insignificant oversight can lead to severe consequences. This highlights the relentless pursuit of precision in the aerospace industry. Every component, regardless of size, plays a crucial role in the overall safety, functionality, and efficiency of an aircraft.

Diving Deep into Advanced Metal Stamping Technologies

The demands of the aerospace industry have driven innovation in metal stamping technology, leading to the development of tailor-made advanced techniques aimed at achieving precision and efficiency:

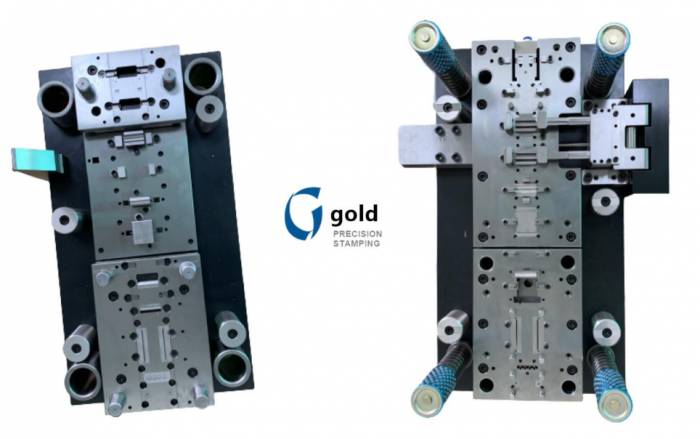

1. **Advanced Die Design**: The design of dies has been refined to ensure that the components produced are not only precise but also consistent. This involves the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) to create complex and intricate dies that can produce components with tight tolerances.

2. **High-Strength Materials**: The use of high-strength materials such as titanium and aluminum alloys is common in aerospace. Metal stamping processes have been adapted to work with these materials, ensuring that the components can withstand the rigors of flight.

3. **Precision Machining**: Beyond the initial stamping process, precision machining is often required to achieve the exact specifications needed for aerospace components. This may involve additional operations such as milling, drilling, or grinding to refine the part's dimensions.

4. **Automated Systems**: Automation has been integrated into metal stamping processes to increase efficiency and reduce the potential for human error. Robotic systems can perform repetitive tasks with high accuracy, ensuring that each component meets the strict quality standards of the aerospace industry.

5. **Quality Control Measures**: Rigorous quality control measures are in place throughout the metal stamping process. This includes in-process inspections, post-process testing, and the use of non-destructive testing (NDT) methods to ensure that components are free from defects.

6. **Environmental Considerations**: The aerospace industry is increasingly focused on sustainability. Metal stamping processes are being optimized to reduce waste, conserve energy, and minimize the environmental impact of component production.

By understanding and implementing these advanced metal stamping technologies, the aerospace industry can continue to produce components that meet the exacting standards required for safe and efficient flight.Progressive Die Stamping (Continuous Stamping): This method involves feeding a metal strip through a series of stamping stations, with each station performing a specific action. It is highly efficient for producing large quantities of complex parts.

Deep Drawing Stamping (Stretching): This technique uses a series of dies to shape the metal into the desired form, making it an ideal choice for manufacturing deep-drawn components.

Micro Stamping (Micro Stamping): For small parts with extremely high precision requirements, micro stamping is the most commonly used technology, capable of producing parts with minute details.

**Key Considerations in Aerospace Metal Stamping**

Material Innovation: As aerospace technology advances, the demand for newer, more resilient materials is increasing. The industry is continuously exploring alloys and composite materials that can offer higher performance.

Sustainability: With the growing global emphasis on sustainable development, the aerospace industry is seeking environmentally friendly stamping processes to minimize waste and carbon footprint.

Collaborative Robots: The integration of collaborative robots (cobots) with metal stamping is expected to enhance precision and efficiency, with robots working alongside humans to optimize the stamping process.

**Looking Ahead: The Future of Metal Stamping in the Aerospace Industry**We are standing on the cusp of a new era in aerospace, marked by space travel and interstellar exploration, where the demands for metal stamping will only increase. Innovative technologies such as quantum computing are expected to revolutionize simulation and testing, while advanced artificial intelligence algorithms will further refine quality control, ensuring that each stamped component is flawless.

Conclusion

Metal stamping, a fusion of ancient techniques and cutting-edge innovations, remains at the core of the aerospace industry. As we soar to new heights and explore the final frontiers, the role of metal stamping will only grow larger. Stamping is not just about shaping metal; it is about crafting the future of aerospace with each and every stamped part.

Join the Conversation