The metal stamping project is a complex dance of design, precision, and execution. Let's unravel the entire lifecycle of these projects from the initial concept to the final product.

The lifecycle of a metal stamping project encompasses stages from design conception, material selection, prototyping to final production, ensuring accuracy and quality at every step.

Delve into the intricate processes and innovations that bring metal stamping projects to life.

Conceptualization and Design

Every metal stamping project begins with an idea, a vision. This initial phase is often overlooked but is the foundation of the entire project. It is where dreams are translated into actual designs and where the journey from concept to completion truly begins.

Understanding customer requirements and project objectives

Before any metal enters the stamping press, it is crucial to understand the true needs of the customer. This requires comprehensive discussions, with every detail, no matter how minute, being carefully considered. Questions such as "What is the final use of the stamping part?", "Are there specific weight or strength considerations?" and "What is the expected production volume?" are addressed. This phase ensures that the project aligns with the customer's vision and objectives, setting a clear roadmap for subsequent stages.

Preliminary sketches, CAD designs, and feasibility analysis

Once the requirements are clear, the design phase begins. Preliminary sketches are drawn, providing a rough visual representation of the final product. These sketches are then transformed into detailed CAD (Computer-Aided Design) models, offering a three-dimensional perspective and allowing for complex detail handling.But design is not just about aesthetics. It also pertains to functionality and feasibility. After the CAD design is completed, a feasibility analysis must be conducted. This step takes into account factors such as material properties, mold limitations, and production costs to assess whether the design can be practically stamped. This is a crucial phase to ensure that the design is not only visually appealing but also manufacturable.

Essentially, the conceptualization and design phase is a fusion of creativity and pragmatism. During this stage, the client's vision is combined with the realities of production, laying the groundwork for the magic of metal stamping to unfold.

Material Selection

In the field of metal stamping, the choice of materials is of paramount importance. It's not just about selecting a metal, but choosing the right metal that perfectly aligns with the project objectives. This decision impacts everything from the manufacturing process to the final product performance.

Selecting the Appropriate Metal Based on Project Requirements

Different projects have different needs. Components designed for aerospace applications have vastly different requirements compared to those designed for household appliances. Factors such as corrosion resistance, conductivity, thermal properties, and weight play a significant role in the decision-making process.

For example:

Aluminum is lightweight and corrosion-resistant, making it a preferred choice for automotive and aerospace applications.

Stainless steel is known for its strength and rust resistance, making it the top choice for medical devices and kitchen utensils.Copper has excellent electrical conductivity, making it the preferred choice for electrical connectors and circuits.

The choice is not always that simple. Alloys, which are combinations of two or more metals, are often selected to take advantage of the best characteristics of each constituent metal.

Consider strength, flexibility, and ultimate use

Each metal has its unique properties. Some metals are hard and rigid, while others possess ductility and flexibility. The key is to match these properties with the project requirements.

Strength: For components that need to withstand loads or pressures, metals with high tensile strength should be the first choice. This ensures that the components do not deform or break under pressure.

Flexibility: Some projects, especially those that require complex designs or deep drawing, need metals that can be bent into shape without breaking. For such applications, metals with good ductility are chosen.

Ultimate use: The environment in which the final product will be used also determines the choice of material. For instance, components exposed to seawater may require metals that are resistant to seawater corrosion. Similarly, components used in high-temperature environments also need metals that can withstand high temperatures without losing their properties.

In summary, material selection is a delicate balance of science and art. It requires a deep understanding of metallurgy and a clear vision of the project goals. The right material choice ensures that the final stamped components are not only aesthetically pleasing but also perform flawlessly in their intended applications.

Prototyping and testingOnce the design and materials are determined, the next critical step in the life cycle of a metal stamping project is the creation of prototypes. At this stage, theory and practice are combined to transform ideas into tangible samples, ready for rigorous testing.

Creating Initial Samples for Validation

Prototype making serves as a bridge between design and mass production. It is the process of creating a limited number of samples that represent the final product. These prototypes serve multiple purposes:

- Verification of design: Prototypes bring CAD designs to life, allowing for practical assessment. They help identify any discrepancies between the design and the actual product.

- Functional testing: Beyond aesthetics, prototypes are used to test whether the components function as intended. Does it fit where it is supposed to? Can it effectively perform its task?

- Gathering feedback: Prototypes can be shared with stakeholders, including customers, to collect feedback. This early feedback is invaluable for making necessary adjustments before mass production.

Stress Testing, Durability Assessment, and Design Improvement

Once the prototypes are ready, a series of stringent tests are conducted:

- Stress testing: These tests subject the samples to the forces and pressures they may encounter throughout their life cycle. The aim is to ensure that the components can withstand these stresses without deforming or breaking.

- Durability assessment: How long will the part last? Durability tests often involve repeated use or exposure to harsh conditions, helping to answer this question. For metal stampings, this may involve repeated bending, exposure to corrosive environments, or temperature fluctuations.Design Improvements: Based on test results and collected feedback, the design may require adjustments. Perhaps the metal in certain areas needs to be thickened, or perhaps a bent section does not need to be so sharp. These improvements will be incorporated into the design to ensure that the final product is both practical and durable.

Essentially, the prototype design and testing phase is a cycle of creation, testing, feedback, and improvement. It is a meticulous process that ensures the product has the highest quality when it begins mass production, capable of meeting the demands of the real world.

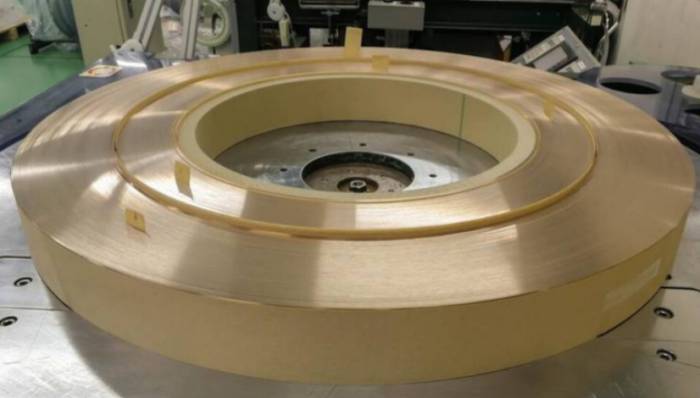

Mold Design

In the field of metal stamping, tools and molds are unsung heroes. They are the molds that shape metal, the tools that imprint design patterns, and the devices that ensure each stamped part is a mirror image of another. The design of these tools and molds is a process of meticulous detail, a perfect combination of engineering precision and craftsmanship.

Creating specialized tools for stamping processes

The complexity of metal stamping projects often requires specialized tools. The purpose of making these tools is to:

Match with materials: Different metals have different characteristics. A tool suitable for aluminum may not be suitable for stainless steel. The design of the tool must take into account the specific characteristics of the chosen metal.

Achieve complex designs: Some projects require complex designs, such as deep drawing or intricate bending. To achieve these designs, specialized tools are needed, which are usually customized for specific projects.

Ensure safety: The design of the tool must not only be precise but also safe. They ensure that there is no danger to the operators during the stamping process.Ensure Precision and Reproducibility in Production

One of the characteristics of metal stamping is the ability to produce a large number of identical workpieces. This reproducibility is achieved through carefully designed dies:

Die Design: Essentially, a die is a mold into which metal is pressed to achieve the desired shape. The design of the die determines the shape, size, and features of the stamped parts. By using advanced CAD tools, die design can achieve the most minute details, ensuring that each stamped part is in complete accordance with the design specifications.

Die Maintenance: Over time, dies can wear out, leading to inconsistencies in the stamped parts. Regular maintenance, including cleaning, grinding, and calibration checks, ensures that the dies remain in optimal condition, producing consistent results.

Quality Inspection: Even with the best-designed tools and dies, regular quality inspections are essential. Regularly inspecting samples from the production line according to design specifications ensures that production remains on track.

In summary, the die design phase is a combination of engineering and artistry. This phase requires precision, foresight, and a deep understanding of the stamping materials and the requirements of the final product. It lays the foundation for the mass production phase, ensuring that each stamped product is a testament to quality and craftsmanship.

Mass Production

The mass production phase is the culmination of all careful planning, design, and prototyping. It is during this stage that the metal stamping project truly comes to life, with products emerging one after another, each a testament to precision and quality. However, scaling up from a few prototypes to large-scale production is not an easy task. It requires strict processes, stringent quality control, and keen attention to detail.

Scaling Up from Prototypes to Full ProductionTransitioning from a small number of prototypes to tens of thousands or even millions of units requires a coordinated and consistent effort:

Setup and Calibration: Press machines are equipped with meticulously designed tools and dies, preparing them for production. This includes calibrating the machines to ensure they operate under the optimal parameters for the chosen materials and designs.

Pilot Run: Before commencing full-scale production, a pilot run is typically conducted. This involves producing a small batch and then thoroughly inspecting for any discrepancies. The pilot run helps identify any potential issues before they affect mass production.

Increasing Output: Once the pilot run is deemed successful, the production is ramped up. Modern press machines can produce an astonishing number of products in a short amount of time, ensuring timely delivery even for large orders.

Quality Control, Batch Testing, and Continuous Monitoring

As the machines hum and production is in full swing, the focus shifts to ensuring the consistency of quality:

Quality Control: Every product that comes off the production line reflects the project's quality standards. Regular inspections are conducted both visually and using precision measuring instruments to ensure that each product meets the design specifications.

Batch Testing: While continuous checks are important, batch testing is another form of quality assurance. Samples are regularly drawn from production batches and subjected to rigorous testing to check strength, durability, and other relevant parameters.

Continuous Monitoring: Modern press machines are equipped with sensors and monitoring systems. These systems provide real-time feedback and alert operators when any parameters go out of the specified range. This continuous monitoring ensures that any potential issues are detected and corrected promptly, minimizing waste and ensuring consistent quality.

Essentially, the mass production phase is a symphony of man and machine. Here, the vision of the project becomes a reality, with each stamped part bearing the mark of excellence, precision, and quality.Finishing and Post-processing

After the production of required parts through the metal stamping process, the entire process is not yet complete. These parts typically undergo various surface treatments and post-processing to enhance their appearance, improve their durability, or add specific functional attributes. This stage is crucial as it ensures that the final product not only fulfills its intended functions but also boasts excellent aesthetics and tactile qualities.

Surface Treatment, Painting, and Coating

Unfinished stamped parts, though functionally robust, may not always possess the desired appearance or resistance to environmental factors. This necessitates surface treatment:

Surface Treatment: This is a process that alters the metal surface to achieve specific effects. For instance, processes like sandblasting or polishing can be used to smooth surfaces, removing any imperfections or rough edges.

Painting: Painting serves a dual purpose. Aesthetically, it gives the stamped parts their final color and appearance. Functionally, it can provide a protective layer to shield the metal from corrosion, especially for components exposed to harsh environments.

Coating: In addition to paint, metals can be coated with other materials to impart specific properties. For example, a zinc coating can enhance corrosion resistance. Similarly, a Teflon coating can be used to provide a non-stick surface.

Ensuring the Final Product Meets Aesthetic and Functional Requirements

The finishing and post-processing stages are guided by the requirements of the final product:Aesthetic Requirements: For components that are visible in the final product, aesthetics play a crucial role. Surface finishing must be smooth, flawless, and consistent in color and texture. Any logos or branding elements must be clearly visible.

Functional Requirements: Depending on the end-use, stampings may need to be corrosion-resistant, heat-resistant, or have reduced friction. Select post-processing methods based on these requirements to ensure that the components perform optimally in their intended applications.

In summary, the finishing and post-processing stages are where the stamped metal truly transforms into a finished product. It is a fusion of art and science, ensuring that each product is not only functional but also provides visual and tactile pleasure.

Quality Assurance and Delivery

The culmination of a metal stamping project is not just about producing parts but also ensuring that each part meets the highest quality standards. Once the final polishing is complete, the focus shifts to rigorous quality assurance and then to the logistics of delivering the finished goods to the customer.

Final Inspection and Quality Check

Before any product leaves the factory, it undergoes a series of final checks:

Visual Inspection: Each component is visually inspected for any surface imperfections, inconsistencies in paint or coating, and overall appearance. This ensures that the product maintains aesthetic standards.

Functional Testing: Depending on the intended function of the component, it may be subjected to specific tests. For example, a stamped metal part designed as a hinge may undergo tests for mobility and load-bearing capacity.Dimension Inspection: Utilize precision instruments such as calipers and micrometers to measure the dimensions of components, ensuring they adhere to the design specifications.

Documentation Verification: Concurrently with physical inspections, relevant documents (such as certificates of conformity or material test reports) are also verified. This provides additional assurance of the component's quality and compliance with standards.

Packaging, Logistics, and Delivering Finished Goods to Customers

Once quality assurance is completed, the focus shifts to delivering the product to the customer:

Packaging: Components are carefully packaged to prevent any damage during transportation. Depending on the product and its fragility, materials such as bubble wrap, foam, or custom packaging may be required.

Logistics: Delivery logistics are planned considering factors like delivery deadlines, destinations, and modes of transport. Whether by land, air, or sea, the goal is to ensure timely and safe delivery.

Communication: Maintain open communication with the customer throughout the delivery process. They will be kept informed about the shipping status, expected delivery dates, and any potential delays.

Feedback and After-Sales Support: After product delivery, we seek feedback from the customer. This feedback is invaluable for gaining insight into any potential areas for improvement. Additionally, after-sales support ensures that the customer has a point of contact in case of any queries or issues.

Essentially, the "Quality Assurance and Delivery" phase is the final link in the metal stamping project. During this stage, all the hard work is validated, and the finished products begin their journey to the customer's hands, serving their intended purpose.Feedback and Iteration

The completion of a metal stamping project and the delivery of the final product do not mark the end of the entire process. In fact, it signifies the beginning of an important phase that ensures continuous improvement and refinement. This stage revolves around gathering feedback and iterating based on the insights obtained.

Collecting Customer Feedback After Delivery

Once the product is in the hands of the customer, their feedback becomes invaluable:

Direct feedback: Engage with the customers to understand their experience with the product. Are they satisfied with the quality? Does the product meet their expectations and requirements? This information can be collected through direct conversations, surveys, or feedback forms.

Performance feedback: Beyond first impressions, understanding how the product performs in its intended application is crucial. Can it withstand the stresses it is subjected to? Are there any unexpected issues during use?

Aesthetic and functional feedback: While the product may be perfect in terms of functionality, customer feedback on its aesthetics, feel, and user experience can provide insights that may not have been considered during the design phase.

Continuous Improvement and Refinement for Future Projects

Feedback is not just about knowing what is right or wrong. It is about learning and iterating:

Analyzing feedback: Analyze all the feedback received to identify patterns. Are multiple customers pointing out the same issue? Is there a certain aspect that consistently receives praise?

Identify areas for improvement: Based on the analysis, pinpoint areas where improvements can be made. This could be in terms of design, manufacturing processes, or customer service.

Implement changes: Make the necessary changes to address the identified issues and enhance the product or service. This could involve redesigning certain components, refining production techniques, or improving communication with customers.

Monitor and evaluate: After implementing the changes, continue to monitor the product's performance and customer satisfaction. This ongoing process helps to ensure that the product continues to meet or exceed customer expectations and that any new issues are quickly addressed.Implement Changes: Based on feedback analysis, modifications can be made to the design, material selection, production process, or any other relevant aspects. This ensures that the same issues do not arise in future projects.

Knowledge Sharing: Insights gained from one project are shared across the entire team. This ensures that everyone is on the same page and that knowledge acquired from one project can benefit future projects.

Customer Engagement: Involving customers in the entire feedback and iteration process is crucial. This not only helps to better understand the customer's perspective but also builds trust, showing customers that their feedback is valued and incorporated.

The "feedback and iteration" phase is a pillar of continuous improvement. It ensures that the processes of each project are refined, the products are improved, and customer relationships are strengthened.

---

Conclusion

The lifecycle of a metal stamping project demonstrates the industry's commitment to precision, quality, and customer satisfaction. By understanding each stage, we can appreciate the craftsmanship and innovation involved in transforming metal sheets into functional masterpieces.

Comment