Entering the world of manufacturing, explore the intricacies of obtaining top-tier progressive die stampings.

To achieve high-quality progressive die stampings, it is essential to ensure a collaborative design process, ongoing employee training, investment in advanced technology, and the establishment of a robust feedback loop.

Join us in delving deep into the evolution of progressive die stamping, from the vast industrial park to meticulous attention to every detail of each stamping.

Background: Industrial Park

As I approached the "Progressive Die Stamping Center of Excellence," I was immediately struck by the grandeur of its facade. This colossal structure, with its gleaming metal and glass exterior, stands as a testament to the marvels of modern manufacturing. At the entrance, the company's emblem is displayed, symbolizing precision and quality.

Where I am

Standing outside, I quietly absorbed the atmosphere. The rhythmic hum of machinery echoed in the background, forming a symphony of mechanics. It was like the heartbeat of the factory, each beat representing a piece of metal being shaped, molded, and perfected. The air was filled with a mix of anticipation and excitement, as workers clad in protective gear busied themselves purposefully, preparing for a new day's work.

The ground vibrated gently beneath my feet, subtly reminding me of the power here. Trucks loaded with raw materials lined up in the shipping area, while finished products were dispatched from the other end. The entire production process was like a well-oiled machine, with every component operating harmoniously.

Sunlight poured warmly inside the factory, reflecting off polished surfaces and creating a play of light and shadow. It was a new day, and the "Progressive Die Stamping Center of Excellence" was busily transforming another batch of raw materials into high-quality stampings. From the state-of-the-art equipment to the dedicated employees, perfection was evident everywhere.

As I prepared to enter, I couldn't help but feel a sense of awe. I was about to witness the magic of progressive die stamping up close, where dreams became tangible reality.Process: Witnessing the Miracle in the Making

Upon entering the factory, the vastness of the plant immediately caught my attention. The high ceilings, bright lighting, and the fresh scent of newly processed metal filled the air. Everywhere I looked, there was a scene of bustling activity, fully reflecting the complexity of the manufacturing process.

What I Saw

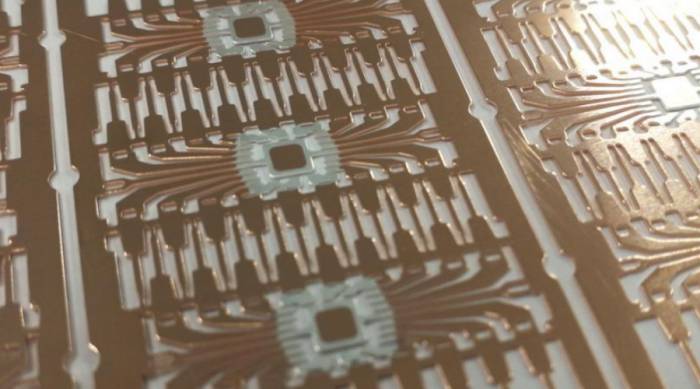

To my left, large sheets of metal were being systematically fed into state-of-the-art stamping machines. With each press, the machine roared, exerting tons of pressure to transform flat metal sheets into precisely shaped components. The sound was both powerful and rhythmic, echoing through the factory like a heartbeat.

Workers, wearing safety goggles and gloves, were focused and precise in their movements. They monitored the machines, made adjustments, and ensured that each stamped part met exact specifications. Their movements were smooth and skilled, the result of years of experience and training.

Further along, a group of engineers were huddled around a computer workstation. They were intently staring at the screens, analyzing design blueprints and 3D simulations. Occasionally, someone would jot down a note, suggest an adjustment, or discuss an aspect with a colleague. It was clear that collaboration was key here. Every design element, no matter how minute, was scrutinized and optimized for perfection.

Next to the engineer workstation, I noticed a quality control area. Here, freshly stamped parts were being inspected under bright lights and magnifying glasses. Measurements, checks for tolerances, and prompt handling of any deviations were taking place. The commitment to quality was evident in every corner of the factory.

As I continued my tour, I was struck by the seamless integration of man and machine. It was a dance of precision and passion, with every move calculated and every outcome a testament to the art and science of metal stamping. I was fortunate to witness a magical scene.Personnel: Meeting with Experts

As my understanding of the factory deepens, the human element within this vast industrial complex becomes increasingly evident. While machinery and technology play a crucial role, it is the employees who breathe life into the process, ensuring that each stamped part is a testament to craftsmanship and dedication.

The People I Met

Maya, Factory Manager: Maya is a dynamic and authoritative figure who greeted me with an enthusiastic smile. Her eyes sparkled with passion as she spoke about the factory and its operations. "Every day is a new challenge," she said, "but seeing ideas transform into tangible products is incredibly meaningful." As we walked, she pointed out various parts of the factory, explaining the intricacies of the stamping process and the relentless efforts to improve efficiency and quality. She expressed immense pride in her team and their achievements.

Raj, Quality Control Specialist: Maya introduced me to Raj, a tall gentleman with a keen eye for detail. Raj's role is pivotal—he is responsible for ensuring that every stamped part meets the highest quality standards. He showed me various testing equipment, from tensile strength testers to dimensional accuracy checkers. "Precision is non-negotiable here," Raj emphasized. He spoke about the rigorous tests each part undergoes and the feedback loops in place to ensure continuous improvement. "It's not just about meeting standards, but about exceeding them," he added.

As we continued the tour, I had the opportunity to chat with several other employees. Each had their unique story, but a common thread ran through their narratives—a sense of pride in their work and a commitment to excellence. Machine operator Elena shared her story of training and the satisfaction she gained from seeing perfect stamped parts emerge from the machine she operates. Another worker spoke about the collaborative environment here and how everyone's input is valued.

The staff behind the machines, the experts who ensure that every stamped part is a masterpiece, are the true heroes of this factory. Their dedication, expertise, and passion are the driving forces behind the magic of metal stamping. It is evident that while machinery and technology are important, it is the human touch that makes all the difference.

Reflections: Experience and Insight

As I take a moment to reflect, the enormity of the operation and the intricate dance between man and machine have left an indelible mark on my mind. This place is not just where metal is stamped; it is also the hub of innovation, collaboration, and relentless pursuit of excellence.What I'm Thinking

Attention to Detail: Every nook and cranny of the factory, every machine, and every stamping part bear testament to their meticulous attention to detail, which is the hallmark of their operations. It is evident that they spare no effort to ensure that each product meets the highest standards of quality and precision. This pursuit of detail is not just about meeting industry standards, but about setting new benchmarks for excellence.

Interdepartmental Synergy: One of the most striking aspects is the seamless collaboration between different departments. Designers, engineers, machine operators, and quality control experts work in concert, each fulfilling their roles to perfection. This collaborative approach ensures that ideas are translated into products with precision and efficiency. It fully embodies the factory's team spirit and shared vision.

The Importance of Continuous Innovation: The world of manufacturing is evolving rapidly, with new technologies and processes emerging all the time. The factory's adoption of the most advanced machinery, sophisticated software, and cutting-edge technology fully demonstrates its commitment to continuous innovation. However, beyond technology, what truly sets them apart is a mindset of constant improvement and a relentless desire to strive for better.

As I prepared to leave, I realized that my visit to the progressive die stamping industrial park was not just an eye-opening experience, but a journey into the heart of modern manufacturing. In this world, dreams gradually take shape, visions become reality, and the limits of the possible are continually pushed. The heartbeat of modern manufacturing is strong and vibrant, fueled by passion, precision, and a steadfast commitment to excellence.

Key Points: Pillars of Quality Stamping

As I conclude my enlightening journey through the progressive die stamping industrial park, I have discovered certain pillars that form the foundation of their success. These important insights not only define the essence of quality stamping but also serve as guiding principles for any industry striving for excellence.

Collaborative Design:

When designers and machine operators come together to merge creativity with practicality, that's when the magic truly begins. This synergy ensures that every design is not only innovative but also feasible, leading to efficient and high-quality outcomes. By bridging the gap between concept and execution, collaborative design ensures that each stamping part meets the expected specifications.Continuous Training:

In an industry that evolves rapidly, staying up-to-date is not a luxury but a necessity. The factory is committed to ongoing training to ensure that every employee, from machine operators to quality control experts, masters the latest technologies and knowledge. This culture of learning and growth ensures that the team is always at the forefront, ready to confidently face new challenges.

Technology Investment:

Quality stamping requires both technology and tools. The factory's investment in state-of-the-art machinery and advanced software demonstrates their commitment to precision and excellence. By harnessing the power of technology, they are able to achieve unparalleled accuracy, reduce waste, and enhance overall efficiency.

Feedback Loop:

The pursuit of perfection is an ongoing process, and feedback plays a crucial role in it. By establishing robust feedback channels, both internally among departments and externally with customers, the factory ensures that it remains aligned with market demands and team aspirations. This culture of open communication and continuous improvement ensures that they are always at the cutting edge of the stamping industry.

In conclusion, high-quality stamping is not just about shaping metal; it is about shaping dreams, visions, and ambitions. It is driven by collaboration, innovation, and a deeply ingrained commitment to quality, relentlessly striving for excellence. The Progressive Die Stamping Center of Excellence "shines like a bright lighthouse, illuminating the union of passion and precision, and also the realization of dreams.

---

Conclusion

Progressive die stamping is not just a manufacturing process; it is an art form that requires collaboration, innovation, and dedication. By understanding its complexities, we can truly appreciate the quality of the stampings that shape our world.

Join the Conversation