Why is the material important in stamping?

A brief introduction to the key role of materials in determining the success or failure of stamping projects.

Material properties determine the success or failure of the project

One of the most critical decisions when starting a stamping project is the selection of materials. This is not just a formal decision, but one that affects the success or failure of the project. The reasons are as follows:

Strength and durability: Imagine creating a beautiful component, only for it to deform or break under the slightest pressure. The strength of the material determines its ability to withstand external forces. Whether it is the pressure of stamping or the stresses faced in the final application, the material must maintain its shape and integrity. For example, automotive parts require materials that can withstand the harsh environment of daily use without deformation.

Ductility: On the other hand, while strength is crucial, the material's ability to be shaped is also vital. Ductility refers to the ease with which a material can be stamped, bent, or formed without breaking or cracking. This is particularly important for complex designs or when a high level of detail is required. Too brittle materials may shatter under the stamping press, leading to the waste of resources and time.

Corrosion resistance: No one wants their stamped products to degrade prematurely. Corrosion, which is the gradual destruction of a material due to a chemical reaction with the environment, is a real concern, especially for products exposed to moisture, certain chemicals, or varying pH levels. For example, ship equipment or parts used in chemical factories require materials that are resistant to rusting or corrosion.

Factors affecting material selectionSelecting the appropriate material for a stamping project is not just about understanding different types of metals. It's about choosing based on the specific needs and constraints of the project. Below, we will delve into the factors you should consider:

Project Requirements: This is the starting point. What goals do you want the final product to achieve? If you are manufacturing a part for aerospace applications, you might prioritize materials with a high strength-to-weight ratio. For decorative items, appearance and surface treatment might be more important. For medical devices, biocompatibility is of utmost importance. The characteristics of the material should always align with the functional requirements of the final product.

Budget Constraints: Let's face it; while we would all like to use the best materials, budgets often dictate our choices. Some metals, such as gold or platinum, may be ideal for specific applications but are prohibitively expensive. A balance must be struck between quality and cost. Sometimes, this may mean making slight compromises on certain characteristics or considering alloys that offer a range of properties at a more affordable price.

Production Volume: The scale of the project can also influence material selection. If the production volume is limited, you might opt for materials that are slightly more expensive but offer superior performance. However, for projects with large-scale production, even small savings per unit can lead to significant overall savings. Additionally, some materials are easier to supply in bulk, making them more suitable for mass production.

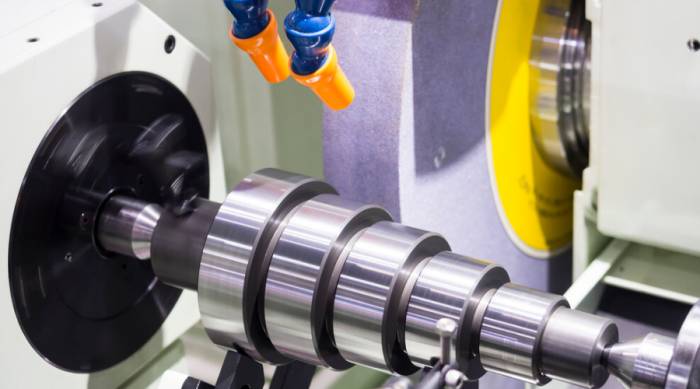

Common Materials and Their Applications

When it comes to metal stamping, the material you choose can make or break the project. Below, we will provide a detailed overview of some of the most commonly used materials in the industry and their advantages:

Steel: Often hailed as the workhorse of the metal stamping field, steel is known for its strength and durability. It is versatile and suitable for everything from automotive parts to construction materials. There are various types of steel, with stainless steel offering greater corrosion resistance and carbon steel gaining enhanced strength after heat treatment.

Aluminum: If you are looking for a lightweight yet strong material, aluminum is your top choice. Aluminum's natural rust and corrosion resistance make it a favorite in industries such as aerospace and automotive, where weight and durability are paramount. Additionally, aluminum has excellent ductility, allowing for complex designs without compromising structural integrity.

Copper: Beyond its beautiful reddish-brown color, copper boasts excellent electrical conductivity. This makes it the preferred choice for electronic components, wiring, and circuits. Copper also has good ductility, allowing it to be stamped into thin sheets without losing its properties. Furthermore, copper's natural antimicrobial properties have led to its widespread use in medical and sanitary applications.Brass: Brass is an alloy of copper and zinc, combining the advantages of both metals. It is both strong and ductile, making it highly suitable for intricate embossing projects. Its golden appearance is commonly used for decorative items, musical instruments, and hardware. Additionally, its corrosion and wear resistance ensure its longevity.

When selecting materials, it is important to consider not only their inherent properties but also how they match the specific requirements of the project. Each material has its own strengths, and understanding these strengths can help you make informed decisions to ensure the success of stamping work.

Specialty Materials for Special Applications

In the vast world of metal stamping, some materials are widely popular for their versatility, while others are chosen for their special properties to meet the needs of special applications. Let's delve deeper into these specialty materials:

Titanium: Often referred to as the "space-age metal," titanium boasts an impressive strength-to-weight ratio. Its strength is almost on par with steel, but it is only half the weight of steel. This unique combination makes it a sought-after material in the aerospace and medical industries. Titanium's natural corrosion resistance, even to saltwater, further increases its appeal, making it the preferred choice for marine applications and surgical implants.

Inconel: When you need a material that can withstand high temperatures, Inconel is up to the task. This superalloy, primarily composed of nickel, chromium, and iron, is known for maintaining its strength at extreme temperatures. No wonder it is a favorite for jet engine, turbine, and nuclear reactor components. Inconel's oxidation and corrosion resistance also mean it can thrive in harsh environments.

German Silver: Don't be fooled by its name; German silver does not contain real silver. Instead, it is an alloy of copper, nickel, and zinc. German silver has a silver-like luster, making it a preferred choice for decorative items, jewelry, and musical instruments. But German silver is not just about appearance; it is also known for its resistance to tarnishing and corrosion, ensuring that items made from it maintain their shine for a long time.

When undertaking stamping projects with special requirements, exploring these specialty materials is crucial. They may be more expensive, but their unique properties can make them invaluable in certain applications, ensuring the longevity and functionality of the final product.Environmental and Sustainability Considerations

As we move towards a more sustainable future, our choices, especially those made in the manufacturing process, are under intense scrutiny for their environmental impact. When selecting materials for stamping projects, considerations are no longer limited to performance and cost. The ecological impact also plays a significant role. Here's why:

Recyclability: The ability of a material to be recycled at the end of its life cycle is a crucial advantage. For instance, aluminum stands out in this regard. It can be recycled indefinitely without a loss in quality, making it a favorite in industries aiming to reduce their carbon footprint. Steel is also highly recyclable, with the energy consumed in recycling steel being 60% less compared to producing it from raw materials. By choosing recyclable materials, manufacturers not only reduce waste but also conserve energy and resources.

Sourcing: The location and method of material procurement can have a profound impact on its environmental footprint. Sustainably mined or produced materials ensure that the extraction process does not harm the environment. For example, conflict minerals mined under conditions of armed conflict and human rights abuses have gained global attention. Ethical sourcing ensures that materials are obtained in a responsible manner that does not harm society or the environment.

Carbon Footprint: Some materials require a significant amount of energy during production, leading to increased carbon emissions. By choosing materials with a lower carbon footprint or those produced using renewable energy, manufacturers can further reduce their environmental impact.

Disposal: Harmful or non-degradable materials pose challenges to the environment when disposed of. Selecting materials that are biodegradable or can be safely disposed of is crucial for minimizing long-term environmental harm.

Incorporating these considerations into material selection not only aligns with global sustainability goals but also resonates with environmentally conscious consumers, adding extra appeal to the final product.

Case Study: Successful Material Selection in Stamping Projects

Material selection can make or break a project, especially in industries that demand high standards of precision, durability, and sustainability. Let's delve into some real-life cases where the right material choice played a vital role in the success of the project.Tesla's Use of Aluminum: The electric vehicle giant Tesla has always been at the forefront of innovation. One of their masterstrokes is the decision to use aluminum as a body material, especially for the Model S. The reduction in weight leads to improved energy efficiency, allowing the car to travel a longer distance on a single charge. Additionally, the corrosion resistance of aluminum ensures the longevity of the car, even under harsh environmental conditions. Tesla's choice is not only for performance but also for sustainable development, as aluminum is recyclable.

Apple's Shift to Recycled Aluminum: As a byword for innovation, Apple Inc. has made headlines for its commitment to sustainable development. A significant step they have taken in this regard is the decision to use 100% recycled aluminum in their products starting with the MacBook Air and Mac mini. This transition not only reduces the carbon footprint associated with aluminum production by nearly 50% but also sets a precedent for other tech giants to follow. Apple's choice demonstrates that sustainable development and high quality can go hand in hand.

These two case studies emphasize the importance of material selection, not only from a functional perspective but also from an environmental and branding perspective. Making wise choices can lead to better products and a better planet.

Common Mistakes to Avoid When Selecting Materials

From cost to durability, material selection is a delicate balance of various factors. However, even seasoned professionals sometimes overlook key factors, leading to costly mistakes. Here are some common pitfalls and how to avoid them:

Neglecting Material Costs: The allure of high-end materials can be tempting, especially when you want to achieve a quality finish. However, the most expensive materials are not always the best choice for every project. It is essential to weigh the benefits and costs of the material. For instance, titanium's strength-to-weight ratio may be well-suited for aerospace applications, but it could be too expensive (and over budget) for simple household items. Always consider the project budget and the return on investment for the material.

Tip: Conduct a cost-benefit analysis for each material under consideration. This will give you a clearer understanding of which material best meets your specific needs.

Neglecting Long-Term Durability: It is tempting to focus on immediate needs when selecting materials. However, considering the entire lifecycle of the product is crucial. A material that seems perfect now may degrade faster than anticipated, leading to increased maintenance costs or even product recalls. For example, a metal with good ductility may be easy to stamp but could be prone to dents and damage in the long run.

Tip: Always consider the environmental conditions the final product will be exposed to. This includes temperature fluctuations, potential contact with chemicals, and physical wear and tear. Choose materials that can withstand these conditions within the expected lifespan of the product.The Future of Stamping Material Selection

Like many industries, the field of metal stamping is constantly evolving. As technology advances and global priorities shift, the criteria for material selection have become more diversified. Here is a glimpse into the future of stamping material selection:

Smart Materials: Imagine a material that can change its properties in response to external conditions. This is the promise of smart materials. These materials are not just passive components but active participants, capable of altering their shape, color, or even electrical conductivity in response to stimuli such as temperature, light, or pressure. For instance, in the medical field, implants made from smart materials could potentially release medication in response to changes in the body, ensuring timely and targeted treatment.

Eco-friendly Alloys: With the growing global awareness of environmental protection, there is an increasing demand for materials that are not only durable and efficient but also environmentally friendly. Currently, researchers are developing new alloys that are designed to minimize their environmental impact from the outset. These materials aim to reduce the carbon footprint during production, enhance recyclability, and minimize waste. For example, some new alloys might incorporate metals with lower energy consumption or use recyclable materials without compromising quality.

Nanotech in Stamping: The potential applications of nanotechnology in metal stamping are vast. By manipulating materials at the molecular or atomic level, it is possible to create metals with enhanced properties, such as increased strength or improved conductivity. This will revolutionize the types of metal stamping products available.

Making Informed Decisions

Selecting the appropriate material for a stamping project is not just a technical decision; it is also an art. It requires understanding the delicate balance between functionality, aesthetics, cost, and sustainability. As we explore the complex process of material selection, one thing is clear: the materials you choose can make or break a project.

In the ever-evolving field of metal stamping, it is crucial to stay informed about the latest trends, technologies, and materials. However, beyond technical knowledge, it is also essential to understand the broader context. The choice of each material will not only affect the performance of the product but also our environment and society as a whole.Therefore, when you embark on your next stamping project, take a moment to reflect. Consider the long-term impact of material selection. Prioritize quality and sustainability. And always put the core requirements of the project at the forefront of your decision-making.

In the final analysis, wise decisions are powerful decisions. This is what distinguishes a product that merely exists from one that excels. So, arm yourself with knowledge, ask the right questions, and let your material choices pave the way for success. After all, in the world of metal stamping, the material is not just a component; it is the foundation of your masterpiece.

Comment