Lead frames play a crucial role in semiconductor packaging, yet the complexity they introduce is often overlooked. Delving deeper, we uncover the subtleties that make this component so critical.

Lead frames are thin metal plate components used in semiconductor packaging, such as ICs and LSIs, serving as the foundation for the chips and facilitating connections.

To truly appreciate the significance of lead frames, we must explore the subtle complexities and challenges they bring.

The Role and Fundamentals of Lead Frames

In the complex world of semiconductor packaging, lead frames stand out as foundational components. These thin metal plates are often overlooked, but they are the pillars of semiconductor packaging like ICs and LSIs. Their primary function is to provide a solid foundation for the chips and facilitate their connections, ensuring seamless communication within the device. However, what makes them so critical, and what factors need to be considered when designing them?

Fundamentals of Lead Frames

Lead frames are more than just metal plates; they are precision-engineered components designed to support semiconductor chips and connect them to external circuits. Their design and layout are crucial because they determine how efficiently the chip communicates with the outside world. The pins or leads of the frame not only provide physical support but also act as conduits for electrical signals, powering the chip and transmitting data. Given their importance, understanding the fundamentals of lead frames is necessary for anyone involved in semiconductor design or manufacturing.

Subtleties in Material Selection

The choice of material for lead frames is not arbitrary. Different metals and alloys have their own set of properties, and the right selection can significantly impact the performance of semiconductor packaging. Copper, iron-nickel alloys, and aluminum are preferred materials primarily due to their excellent electrical conductivity. But it's not just about conductivity. Corrosion resistance is another key factor. Lead frames that are prone to corrosion could compromise the performance and lifespan of the chip. Therefore, the selection of materials is often based on a balance between conductivity, corrosion resistance, and other factors such as cost and availability.Thermal Management

Heat is an ongoing challenge in the world of electronics. As devices become more powerful and compact, thermal management becomes even more critical. Leadframes play a key role in this aspect. Their design must ensure effective heat dissipation, preventing the chip from overheating and ensuring optimal performance. This is where material selection comes into play again, as metals with high thermal conductivity can dissipate heat more effectively. But it's not just about the materials. The design, thickness, and layout of the leadframe can all impact its effectiveness in managing heat. Moreover, in high-temperature environments, leadframes must be robust enough to withstand the heat without deforming or losing their properties.

Advantages and Challenges of Using Leadframes

Although leadframes may seem simple, they are crucial to the functionality and efficiency of semiconductor packaging. Their design and integration can significantly affect the performance of the entire device. However, like any component, they have their own set of advantages and challenges, especially in an industry that is constantly evolving and demanding innovation.

Performance Enhancement

One of the main advantages of using leadframes is the significant performance enhancement they provide for semiconductor packaging. By ensuring a stable and efficient connection between the chip and the external circuitry, leadframes facilitate faster data transfer and reduce signal loss. Their design, particularly the layout and spacing of the leads, can optimize signal paths, minimize interference, and ensure clearer communication. Additionally, by helping with effective heat dissipation, they ensure the chip operates optimally without overheating, thus extending the device's lifespan.

Pursuit of Miniaturization

As technology advances, there is a continuous push for devices to become smaller, more compact, and more efficient. This pursuit of miniaturization presents opportunities and challenges for the design of leadframes. On one hand, smaller devices mean that leadframes need to be designed with greater precision, compactness, and fineness. This can lead to challenges in ensuring that leadframes remain robust, efficient, and capable of managing heat effectively. On the other hand, it drives innovation, leading to the development of new materials, designs, and manufacturing techniques that can meet these demands.

Integration Complexity

The complexity of integration is another challenge that comes with the use of leadframes. As devices become more sophisticated, the integration of leadframes into the overall design requires careful planning and execution. This complexity can increase the risk of defects and failures, which can be costly and time-consuming to address. However, it also presents opportunities for innovation in the design and manufacturing processes, leading to more reliable and efficient devices.Integrating lead frames seamlessly into semiconductor packaging is no easy task. The challenge lies not only in ensuring that the lead frame fits perfectly but also in ensuring that it interfaces effectively with other components. The connection technology must be precise to prevent any misalignment or loose connections, which could compromise the performance of the device. Moreover, as semiconductor packaging becomes more complex, integrating the lead frame without interfering with other components or pathways becomes a delicate balancing act. This requires a deep understanding of the entire device's architecture and an overall design approach.

Lead Frame Stamping Solutions

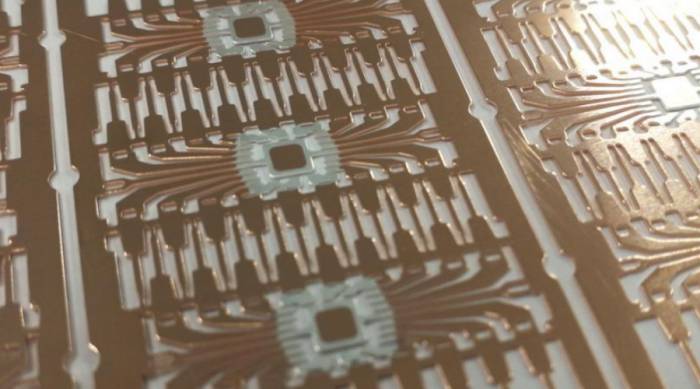

Stamping is a manufacturing process that uses dies to shape metal sheets, playing a crucial role in the production of lead frames. As the semiconductor industry evolves, technologies and methods related to stamping are also advancing, ensuring that lead frames meet the strict requirements of modern devices.

An Introduction to Stamping in Lead Frames

Stamping is a widely adopted method for producing lead frames. It involves the use of dies, which are specialized tools that shape metal sheets into the desired form. This process ensures that each lead frame is consistent in shape and size, which is crucial for the reliability of semiconductor packaging. Considering the precision and scalability that stamping offers, it is no wonder that it has become the preferred method for lead frame production.

Advantages of Stamping in Lead Frames

The stamping process offers numerous benefits in the production of lead frames. First, it ensures precision, guaranteeing that each lead frame is identical, which is essential for mass production. Additionally, stamping is cost-effective when producing lead frames in large quantities. The process is also adaptable, allowing for design modifications without significant alterations to the production line.

Challenges and Solutions in Stamping

While stamping has its advantages, it is not without challenges. Material waste, equipment maintenance, and ensuring consistent quality can pose issues. However, with technological advancements, solutions to these challenges have been developed, such as precision dies, advanced monitoring systems, and automated quality checks, ensuring that the stamping process remains efficient and reliable.Case Study: Advanced Stamping Technology

A notable example is Texas Instruments, a renowned semiconductor manufacturer, and the approach they have adopted. They have implemented advanced stamping techniques to enhance the quality and efficiency of their leadframes. By integrating precision molds with real-time monitoring systems, Texas Instruments has been able to reduce material waste and improve the consistency of leadframes. This not only saves costs but also enhances the overall performance of their semiconductor packaging.

Future Trends in Stamping

As the demand for more compact and efficient semiconductor devices increases, the stamping process will inevitably evolve. Emerging technologies, such as nano-stamp and hybrid stamping methods, are expected to revolutionize the production of leadframes. Additionally, the integration of artificial intelligence and machine learning in the stamping process is anticipated to further improve precision and reduce errors, laying the foundation for the next generation of leadframes.

Cost and Sustainability Considerations

In the rapidly evolving semiconductor industry, the balance between cost, performance, and sustainability is crucial. As the demand for advanced electronic devices grows, so does the need for efficient and sustainable manufacturing processes. Leadframes, being a core component of semiconductor packaging, are no exception.

Balancing Cost and Performance

The production of leadframes is a delicate balance between ensuring top-tier performance and managing costs. High-quality materials and precision manufacturing techniques, while essential for optimal performance, can drive up production costs. However, cutting corners to save costs may compromise the reliability and efficiency of semiconductor packaging.Manufacturers often employ strategies such as bulk purchasing of raw materials, investing in advanced machinery that can reduce waste, and continuous process optimization to achieve the right balance. The goal is to produce lead frames that not only meet performance requirements but are also cost-effective, ensuring that the final semiconductor products remain competitive in the market.

Sustainable Manufacturing

The pursuit of sustainability in manufacturing is more critical than ever before. Amid growing concerns about environmental degradation and resource depletion, the semiconductor industry faces pressure to adopt eco-friendly practices. For the production of lead frames, this means several things:

Material Selection: Choosing materials that are abundant, recyclable, and have a smaller environmental footprint. For example, using alloys that require less energy-intensive refining processes or materials that are responsibly sourced.

Waste Reduction: Implementing manufacturing processes that minimize waste to the greatest extent possible. This includes optimizing stamping techniques to reduce scrap metal and recycling waste where possible.

Energy Efficiency: Investing in machinery and equipment that consume less electricity and optimizing manufacturing processes to improve energy efficiency.

Recyclable Design: Designing lead frames so that they can be easily recycled at the end of their life cycle. This not only reduces the environmental impact but also provides potential cost savings from the reuse of recycled materials in the long run.

Application of Lead Frames in Real-World Cases

Despite the seemingly insignificant components of lead frames, they play a crucial role in the functionality of numerous devices. Their importance becomes even more apparent as we delve into real-world applications and observe the challenges and innovations associated with them.Miniaturization of Mobile Devices

The revolution of smartphones is undoubtedly spectacular. As these devices become more powerful, the demand for compact and efficient semiconductor components has surged. For instance, Apple has been pushing the limits in device miniaturization with its iPhone series. The A14 Bionic chip used in the iPhone 12 series is a testament to this drive. Manufactured using a 5nm process, it integrates 11.8 billion transistors. The lead frame within this chip is meticulously designed to support this level of miniaturization while ensuring optimal performance.

Sustainability in Automobile Manufacturing

The automotive industry is undergoing a transformation towards electric vehicles (EVs). Companies like Tesla are at the forefront of this change. For example, Tesla's Model 3 heavily relies on advanced semiconductor components to manage its battery system, drive system, and infotainment system. The lead frames in these components are not only designed for performance but also with sustainability in mind. Tesla is committed to reducing its carbon footprint, which means that the materials and manufacturing processes of these lead frames are chosen based on their environmental impact, thus promoting more sustainable practices in semiconductor manufacturing.

Cost-Effective Solutions in Consumer Electronics

The consumer electronics market is highly competitive, with companies continually vying for a larger market share. Samsung, as a global leader in consumer electronics, is known for its innovative and cost-effective products. For instance, the Galaxy series of smartphones offers a range of devices targeted at various price points. The semiconductor components in these devices, supported by efficiently designed lead frames, demonstrate Samsung's ability to strike a balance between performance, cost, and reliability. By optimizing the manufacturing process of lead frames, Samsung ensures that its devices remain competitive in terms of price without sacrificing quality.

Conclusion

In the complex world of semiconductor manufacturing, lead frames are often overshadowed by more prominent components, yet they are the unsung heroes. These seemingly simple structures play a crucial role in ensuring that our modern electronic devices, from smartphones to electric vehicles, operate at their best. The numerous challenges and innovations associated with their design and production further emphasize their importance.

The balance between cost, performance, and sustainability in lead frame manufacturing proves the complexity involved. As we have seen, whether it is the pursuit of miniaturization in mobile devices or the push for sustainable solutions in the automotive industry, lead frames are at the core of these technological advancements.Additionally, practical applications and case studies from industry giants such as Apple, Tesla, and Samsung highlight the ongoing innovation in leadframe design and manufacturing. These companies, in their pursuit of perfection, continually push the boundaries of possibility, ensuring that leadframes keep pace with the growing demands of the semiconductor industry.

In summary, as we stand on the threshold of a new era of technological advancement, the importance of leadframes cannot be overlooked. Their role in the semiconductor industry will continue to grow, accompanied by a demand for continuous innovation to ensure their relevance and efficiency in the face of ever-changing challenges.

Comment