Metal stamping is a foundational manufacturing process with a wide range of applications. But where exactly can we see its impact? Let's explore the various uses of metal stamping in our world together.

Metal stamping is a technique that uses specialized dies to shape metal sheets into specific forms. It is primarily used for manufacturing components in industries such as consumer electronics, medical, aerospace, new energy vehicles, communications, and industrial automation.

Interested in the depth and breadth of metal stamping applications? Join us in delving deeper into the multifaceted uses of metal stamping.

Consumer Electronics

Gadgets and Devices

In today's digital age, consumer electronics have become an indispensable part of our daily lives. From smartphones and tablets to laptops and smartwatches, these little devices are everywhere. But have you ever wondered how these devices achieve their stylish designs and precise functions? Enter metal stamping. This manufacturing process plays a key role in shaping the casings, buttons, and even some internal components of these devices. The precision and efficiency of metal stamping make it possible to mass-produce consistent, high-quality parts, ensuring that our gadgets are both aesthetically pleasing and functionally reliable.

Component Manufacturing

In the realm of consumer electronics, metal stamping is crucial for the production of various components. It allows for the creation of intricate parts with tight tolerances, which are essential for the performance and reliability of electronic devices. Whether it's the casing of a smartphone or the internal brackets that hold components in place, metal stamping ensures that these parts are made with the precision needed for modern technology.

Automotive Industry

The automotive industry relies heavily on metal stamping for the production of car parts. From body panels and chassis components to engine parts and suspension systems, metal stamping is used to create strong, lightweight, and durable parts that are critical to the performance and safety of vehicles. The ability to produce complex shapes with high precision and in large quantities is a key advantage of metal stamping in this industry.

Aerospace

In aerospace, metal stamping is used to manufacture components that must withstand extreme conditions. The precision and strength of stamped parts are essential for the performance of aircraft and spacecraft. Components such as engine parts, wing flaps, and structural components are often made using metal stamping techniques to ensure they meet the rigorous standards required for flight.

Medical Devices

The medical industry also benefits from metal stamping, particularly for the production of precision instruments and components. Metal stamping allows for the creation of small, intricate parts with the exact specifications needed for medical devices. This precision is critical for the safety and effectiveness of medical equipment, whether it's a surgical instrument or a component of a diagnostic machine.

Industrial Automation

In industrial automation, metal stamping is used to create parts for machinery and systems that require high levels of precision and durability. From gears and bearings to brackets and housings, metal stamping provides a cost-effective and efficient way to produce parts that can withstand the demands of industrial environments.

In conclusion, metal stamping is a versatile and essential process that impacts a wide array of industries and applications. Its ability to produce precise, high-quality parts in large quantities is a key factor in the advancement of technology and the manufacturing of the devices and components that we rely on every day.Beyond the visible exterior of electronic devices lies a complex network of circuits and components that power their operation. These components, often inconspicuous yet crucial, are manufactured through a precise metal stamping process. Connectors, heat sinks, shielding covers, and a variety of other electronic components are punched from metal sheets according to exact specifications. This precision is vital, as even the slightest deviation can affect the performance of the device. Metal stamping ensures that each component fits perfectly and functions as intended, playing a silent yet indispensable role in the consumer electronics industry.

Medical Industry

Surgical Instruments

The medical field demands unparalleled precision, especially for tools used in surgical and therapeutic procedures. From scalpels and forceps to clamps and retractors, metal stamping plays a critical role in the manufacturing process of many surgical instruments. These tools are typically made from stainless steel or other biocompatible metals, stamped to exact dimensions to ensure their effectiveness and safety in surgery. The sharpness of a scalpel's edge, the grip of forceps, or the curvature of a surgical hook—all are achieved through meticulous metal stamping processes, ensuring that medical professionals can rely on their tools even in the most critical situations.

Diagnostic Equipment

Accurate diagnosis is the cornerstone of effective healthcare. To achieve this, medical professionals rely on a range of diagnostic equipment, many of which benefit from metal stamping. Components of devices such as X-ray machines, magnetic resonance imaging scanners, and even certain parts of blood testing equipment are manufactured using this process. Housings, brackets, and some internal components are perfectly stamped to ensure the reliability and accuracy of the equipment. In this industry, even the smallest error can have significant consequences, making the precision and consistency provided by metal stamping extremely valuable.Aerospace and Aviation

Aircraft Components

The aerospace industry is renowned for its stringent standards and demands for precision, relying heavily on metal stamping to fabricate various aircraft components. From the outer skin of the aircraft to the intricate parts of the engines, metal stamping ensures that each component is made to exact specifications. Wings, fuselage panels, landing gear assemblies, and even the tiny rivets that hold them together are typically products of this process. Considering the extreme environments these components are subjected to (from high altitudes to varying temperatures and pressures), the precision and durability ensured by metal stamping are crucial. It is this meticulous attention to detail that ensures the safety and reliability of aircraft flight.

Satellite Structures

Beyond the atmosphere, metal stamping parts play a vital role in space exploration, particularly in the construction of satellites. These celestial devices, tasked with communication, observation, or scientific research missions, must withstand harsh space conditions. Metal stamping is used to manufacture structural components of satellites, antenna covers, and even some internal mechanisms. The process ensures that these parts are lightweight yet robust, capable of withstanding the vacuum of space, extreme temperatures, and potential collisions with space debris. As we venture further into the cosmos, the precision and reliability of metal stamping will continue to aid in our deepening understanding of the universe.

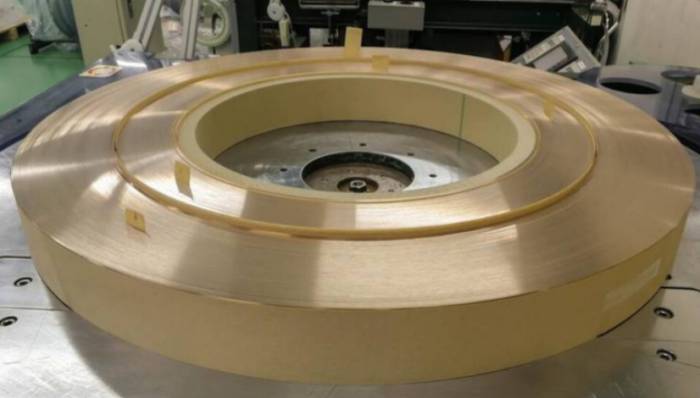

New Energy VehiclesBattery Components

As the world shifts towards sustainable transportation, New Energy Vehicles (NEVs) are at the forefront of this revolution. Batteries are the heart of these vehicles' operation, storing and providing the necessary energy. Metal stamping parts play a crucial role in manufacturing various components of these batteries. From battery casings that protect the cells to connectors that ensure efficient energy transfer, each component is precisely stamped. This ensures the battery's optimal performance, safety, and lifespan, which is essential for enhancing the overall efficiency and reliability of NEVs.

Structural Elements

Given the unique challenges faced by NEVs, such as the installation of heavy battery packs, structural integrity is paramount. Metal stamping is extensively used in the manufacturing of various structural parts for these vehicles. From chassis that form the car's skeleton to body panels that shape the car's exterior, metal stamping ensures that each part is robust, lightweight, and efficient. The process allows for complex designs and shapes to meet the aerodynamic needs of NEVs, ensuring they are both aesthetically pleasing and optimized for their electric propulsion functions.

Communication

Networking EquipmentIn our interconnected world, seamless communication is of paramount importance. At the core of global interconnectivity are the intricate network devices that can facilitate data transmission across continents within milliseconds. Metal stamping components play an indispensable role in the manufacturing of many of these devices' components. Routers, switches, modems, and base stations all contain parts formed through metal stamping processes. These components, whether connectors, housings, or internal circuit supports, are manufactured to precise specifications, ensuring the reliability of data transmission and minimizing potential disruptions in digital communication.

Device Housings

Our communication devices, from smartphones to tablets and laptops, serve as gateways to the digital world. Protecting the delicate electronic components within these gadgets are their housings, many of which are shaped and functionalized through metal stamping processes. These protective casings are typically made of aluminum or other metals, precision-stamped to ensure a snug fit with the internal components. In addition to their protective function, the design of these housings also takes into account aesthetics and ergonomics, with metal stamping processes enabling complex designs, smooth surface finishes, and durable structures that can withstand everyday use.

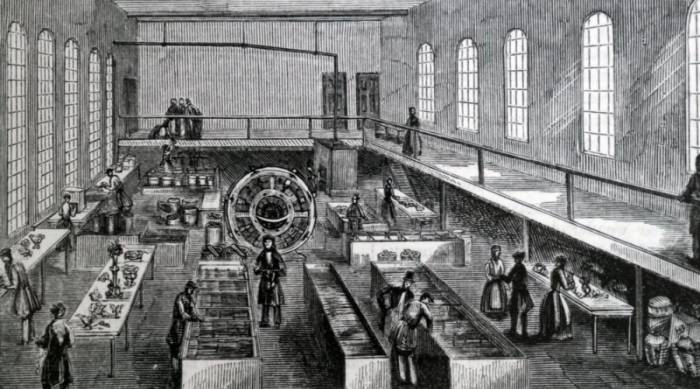

Industrial Automation

Mechanical Parts

As industry has evolved, the pursuit of efficiency and precision has led to a surge in automation. At the heart of this transformation are machines that operate with minimal human intervention. Metal stamping plays a significant role in the fabrication of various parts for these machines. From gears and levers to housings and supports, each component is stamped to exact dimensions to ensure smooth operation. The precision of metal stamping ensures perfect fit and alignment of these parts, reducing wear and extending the lifespan of the machinery. In such environments, even a minor malfunction can lead to significant downtime, making the reliability provided by stamped components invaluable.

Control Systems

Control systems are the brains of automated machinery, directing operations and ensuring that processes run smoothly and efficiently. Metal stamping is crucial in the production of components for these systems, including circuit boards, switches, and connectors. The precision and consistency of metal stamping allow for the creation of components that can withstand the rigors of industrial environments and maintain the integrity of the control systems over time. This precision is essential for the reliable operation of automated machinery, as it ensures that the control systems can accurately process and respond to the data they receive, maintaining the efficiency and safety of the production processes.In addition to mechanical components, industrial automation largely relies on control systems to regulate and supervise operations. These systems typically integrate electronics with mechanics, encompassing numerous parts manufactured through metal stamping processes. The housings that accommodate precision electronic components, connectors that facilitate communication between different parts of the system, and even some sensor components are all products of stamping techniques. Although these components are often overlooked, they are crucial for ensuring that control systems function optimally, maintaining consistent quality, efficiency, and safety in industrial automation processes.

Conclusion

Metal stamping is a seemingly simple yet extremely complex process that has become an integral part of modern manufacturing. Its influence can be seen everywhere, from the small tools we use daily to the cars we drive, and even in the machines that produce other products. From consumer electronics to aerospace, medical, communication, and industrial automation, the precision and efficiency of metal stamping make it an indispensable tool across various industries.

The versatility of metal stamping allows it to meet the unique needs of each industry, ensuring that products are not only functional but also durable and aesthetically pleasing. In our exploration of the various applications of metal stamping, we have found that it is not just a manufacturing process; it is also an art form that skillfully combines technical prowess with creativity.

In an era where quality, efficiency, and sustainable development are paramount, metal stamping stands as a beacon of modern excellence in manufacturing. As industries continue to evolve, there is no doubt that the role of metal stamping will remain significant, driving innovation and shaping the production methods of the future.

Join the Conversation